Exploring the Advantages of Fillet Welding in Construction: Cost-effective Solutions for Diverse Industries

In the realm of manufacture, the utilization of fillet welding presents a compelling proposition for industries seeking economical solutions without compromising architectural integrity. The benefits of fillet welding prolong beyond plain financial savings to incorporate improved architectural effectiveness, versatility throughout diverse commercial applications, and the guarantee of remarkable stamina and longevity. As we navigate through the useful advantages that fillet welding offers, a deeper understanding arises of how this welding method can transform manufacture procedures throughout various industries.

Cost-Effective Service for Manufacture

Fillet welding acts as an economical remedy in construction procedures, giving both performance and resilience. This welding technique includes joining 2 items of metal at an angle, developing a triangular cross-section. The simpleness of fillet welding makes it a preferred option in various markets, consisting of building and construction, automobile, and production.

One of the essential advantages of fillet welding is its ability to lower material and labor costs. By utilizing fillet welds as opposed to other complicated joint styles, manufacturers can save cash on materials and production time. In addition, fillet welding calls for marginal prep work compared to other welding strategies, further reducing manufacture prices.

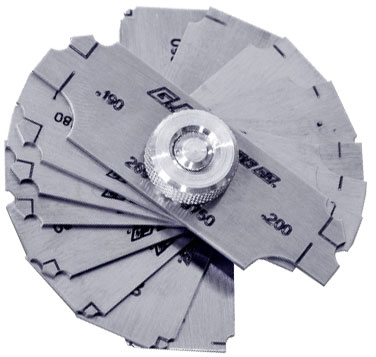

Furthermore, fillet welds provide outstanding structural strength, making certain the longevity and sturdiness of the made parts. The triangular form of the weld disperses stress extra uniformly, lowering the chance of joint failing (Gauge Fillet Weld). This structural integrity not only improves the general quality of the ended up product yet additionally reduces repair and maintenance expenses over time

Improved Architectural Efficiency With Fillet Welding

Enhancing architectural effectiveness with the application of fillet welding methods is a critical aspect of ensuring ideal performance and resilience in produced frameworks. Fillet welding plays a crucial role in enhancing structural efficiency by effectively distributing lots and tensions throughout the welded joints. By creating a smooth transition between the connected parts, fillet welds help to enhance the general toughness and stability of the structure.

Among the considerable advantages of fillet welding in enhancing structural effectiveness is its capacity to join products of differing densities. This adaptability enables for the building and construction of light-weight frameworks without jeopardizing on stamina. Furthermore, the smooth account of fillet welds minimizes stress concentrations, which can aid prevent premature failure of the welded joints.

Furthermore, fillet welding allows the manufacture of complex geometries easily, supplying designers with more freedom in producing innovative and efficient frameworks. By enhancing the style and placement of fillet welds, engineers can make the most of the architectural efficiency of fabricated components, eventually leading to set you back savings and improved performance in diverse markets.

Flexibility in Diverse Sector Applications

With its capacity to cater to a vast array of material densities and geometric intricacies, fillet welding stands as a versatile manufacture method that discovers applications throughout varied sectors. One essential location where fillet welding excels remains in the production market, where it is used in the production of hefty equipment, tools, and architectural elements. The automotive industry also gains from fillet welding, utilizing it in the assembly of lorry frames, chassis, and various other important frameworks. In the building area, fillet welding plays an important role in joining steel beams, columns, and other architectural components. Furthermore, the aerospace industry relies upon fillet welding for the construction of airplane parts, making certain stamina and durability in crucial components. Furthermore, the oil and gas sector makes use of fillet welding in the building of pipes, platforms, and storage containers, where the robust welds provide stability and durability to these frameworks. Generally, the convenience of fillet welding makes it an important procedure in numerous industries, offering affordable solutions for complex construction demands.

Superior Stamina and Durability

Fillet welding plays an essential duty in achieving these characteristics due to its capability to supply significant strength by dispersing tons evenly throughout the welded Discover More Here joint. As an outcome, structures made using fillet welds show raised durability and can withstand considerable mechanical pressures without endangering their integrity.

The superior stamina and resilience supplied by fillet welding make it a perfect selection for applications in sectors such as construction, auto, aerospace, and production, where architectural stability is extremely important. By utilizing fillet welds in construction, designers and suppliers can make certain that their products fulfill rigid top quality and safety and security requirements while maximizing cost-effectiveness and production effectiveness. Essentially, the remarkable strength and long life provided by fillet welding make it a recommended welding technique for producing sturdy and robust structures throughout varied industries.

Practical Benefits of Fillet Welding

Offered the demonstrated premium strength and resilience in welded joints, the useful benefits of fillet welding expand beyond architectural stability to incorporate performance and cost-effectiveness in construction procedures. try this site One vital useful advantage is the simplicity of fillet welds, which do not need complicated or costly equipment to produce. This simpleness equates into time savings throughout fabrication, as fillet welding can be rapidly applied in various positions without the requirement for fancy arrangements. Additionally, fillet welding enables for boosted efficiency as a result of its convenience in joining various sorts of forms, densities, and products. The versatility of fillet welds makes them suitable for a broad range of applications across varied industries, further adding to cost-effectiveness in producing procedures. The lowered demand for substantial surface area prep work compared to other welding strategies minimizes material waste and decreases production downtime. On the whole, the functional advantages of fillet welding make it a valuable choice for business seeking affordable and effective solutions in construction.

Verdict

In verdict, fillet welding provides a cost-efficient service for manufacture, providing improved architectural performance, versatility in varied industry applications, exceptional stamina, and resilience. The functional benefits of fillet welding make it a preferred option for various construction jobs across different sectors. Its capacity to successfully sign up with products while keeping architectural stability makes it a useful strategy for making certain trusted and high-quality lead to welding applications.

Additionally, fillet welding calls for minimal prep work compared to other welding methods, even more reducing construction prices.

Given the demonstrated superior strength and resilience in welded joints, the sensible benefits of fillet welding expand past architectural stability to encompass effectiveness and cost-effectiveness in manufacture processes - Gauge Fillet Weld.In conclusion, fillet welding uses a cost-effective service for manufacture, supplying improved architectural performance, flexibility in diverse industry applications, exceptional stamina, and sturdiness